Page 119 -

P. 119

โครงการรวบรวมและจัดทําวารสารอิเล็กทรอนิกส์ มหาวิทยาลัยเกษตรศาสตร์

วารสารวนศาสตร 34 (1) : 112-121 (2558) 117

์

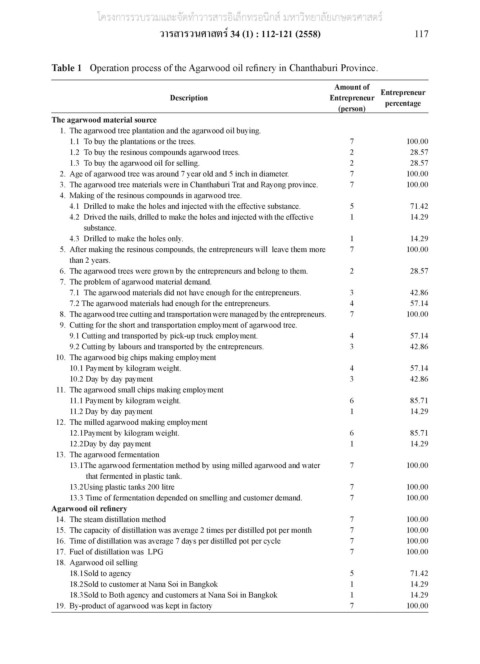

Table 1 Operation process of the Agarwood oil refinery in Chanthaburi Province.

Amount of

Description Entrepreneur Entrepreneur

percentage

(person)

The agarwood material source

1. The agarwood tree plantation and the agarwood oil buying.

1.1 To buy the plantations or the trees. 7 100.00

1.2 To buy the resinous compounds agarwood trees. 2 28.57

1.3 To buy the agarwood oil for selling. 2 28.57

2. Age of agarwood tree was around 7 year old and 5 inch in diameter. 7 100.00

3. The agarwood tree materials were in Chanthaburi Trat and Rayong province. 7 100.00

4. Making of the resinous compounds in agarwood tree.

4.1 Drilled to make the holes and injected with the effective substance. 5 71.42

4.2 Drived the nails, drilled to make the holes and injected with the effective 1 14.29

substance.

4.3 Drilled to make the holes only. 1 14.29

5. After making the resinous compounds, the entrepreneurs will leave them more 7 100.00

than 2 years.

6. The agarwood trees were grown by the entrepreneurs and belong to them. 2 28.57

7. The problem of agarwood material demand.

7.1 The agarwood materials did not have enough for the entrepreneurs. 3 42.86

7.2 The agarwood materials had enough for the entrepreneurs. 4 57.14

8. The agarwood tree cutting and transportation were managed by the entrepreneurs. 7 100.00

9. Cutting for the short and transportation employment of agarwood tree.

9.1 Cutting and transported by pick-up truck employment. 4 57.14

9.2 Cutting by labours and transported by the entrepreneurs. 3 42.86

10. The agarwood big chips making employment

10.1 Payment by kilogram weight. 4 57.14

10.2 Day by day payment 3 42.86

11. The agarwood small chips making employment

11.1 Payment by kilogram weight. 6 85.71

11.2 Day by day payment 1 14.29

12. The milled agarwood making employment

12.1 Payment by kilogram weight. 6 85.71

12.2 Day by day payment 1 14.29

13. The agarwood fermentation

13.1 The agarwood fermentation method by using milled agarwood and water 7 100.00

that fermented in plastic tank.

13.2 Using plastic tanks 200 litre 7 100.00

13.3 Time of fermentation depended on smelling and customer demand. 7 100.00

Agarwood oil refinery

14. The steam distillation method 7 100.00

15. The capacity of distillation was average 2 times per distilled pot per month 7 100.00

16. Time of distillation was average 7 days per distilled pot per cycle 7 100.00

17. Fuel of distillation was LPG 7 100.00

18. Agarwood oil selling

18.1 Sold to agency 5 71.42

18.2 Sold to customer at Nana Soi in Bangkok 1 14.29

18.3 Sold to Both agency and customers at Nana Soi in Bangkok 1 14.29

19. By-product of agarwood was kept in factory 7 100.00